Project description

Extract Microstructure-Property-Process linkages in aging of Al6061 aluminum alloy

Team Members:

Ali Khosravani -Mechanical Engineering

Jordan Weaver - Mechanical Engineering

Project Goals

To find microstructure-Property-Process relations in aging of Al6061 alloy during which grain structure, texture, and precipitate structure evolve.

Details of Datasets

Microstructural features of impact exist at different length scales within the material. For this materials system of interest namely the Al-Mg-Si system and specifically 6061 alloy, the primary microstructural features that will impact properties are:

Coherent GP zones and semi-coherent precipitate particles

These precipitate phases can be revealed by transmission electron microscopy. Key features of each different precipitate phase (mean, std. deviation, and ideally the full distribution) are:

- Volume fraction

- Size (nm)

- Aspect ratio

- Spacing (nm)

These are examples of TEM images of these particles

Al-Fe-Si-type constituent particles

The constituent particles are best revealed by optical metallography both in the as-polished and etched conditions. Again the key microstructural features of interest (mean, std. deviation, and ideally the full distribution) are:

- Volume fraction

- Size (microns)

- Aspect ratio

- Spacing (microns)

These are examples of optical image of these particles

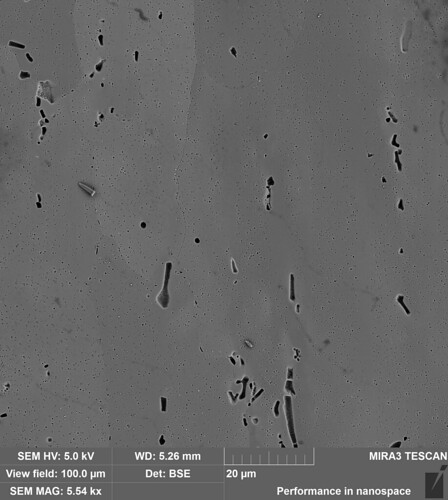

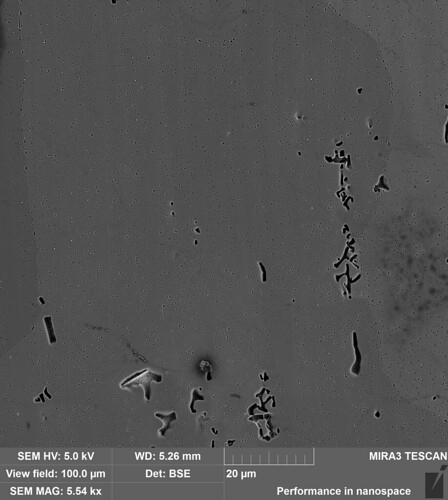

Also BSE detector in SEM can reveal these particles in better contrast and resolution

These are examples of BSE images of as-received sample

These are examples of BSE images of aged sample at 775F for 2hrs

Grain structure, including degree of recrystallization and texture

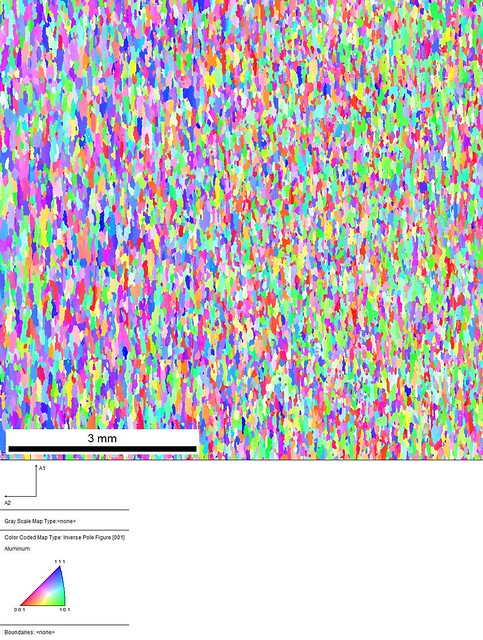

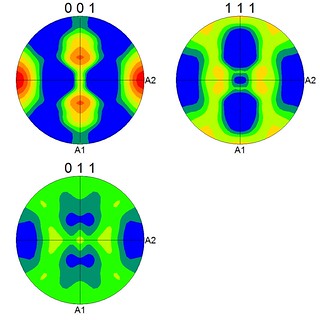

Grain structure can be revealed by optical metallography with suitable etching and scanning electron microscopy (SEM). Crystallographic texture is measured using electron back scattered detection (EBSD) technique. Texture parameters of interest are the strengths of different texture orientations, typically represented in a pole figure. For recrystallized grain structures, the key features (mean, std. deviation, and ideally the full distribution) are:

- Size (microns)

- Aspect ratio

- the strengths of different texture orientations

This is an EBSD datasets for as-received sample and associated pole figures

Proposed Workflow

Experiments

- EBSD datasets are collected from RD plane of as-received sample, and heat treated ones at 775, 650, 525, and 400F for 2hrs.

- Optical and SEM images partially collected for few samples. New etchant has to be used for better contrast in optical micorscopy

- TEM images will be collcted by our collabortor in NIST. (Samples for each heat treatment condition were sent on 09/12/2014 to NIST for TEM purpose) for TEM work

- Mechanical properties from tensile tests will be collected on as-received material along RD, TD and 45 degree (9 tests for each)

- Mechanical properties from tensile tests will be collected on as-received sample, and heat treated ones along RD (9 tests for each)

- Design a new experiments for a high throughput sample such that a tempreture gradient in the sample results in different microstructures

- Mechanical properties from Macroindentation tests along high throughput sample.

This is an FEM simulation of the sample with temperature gradient from 900F to RT

Data analytics

- Extract structure data from collected EBSD, optical and SEM datasets for each heat treating condition

- Volume fraction, Size, Aspect ratio, Spacing of precipitates from OM, EBSD, and TEM

- Size, morphology, and texture of microstructure for grains from EBSD

- Generate statistics from structure data

- Establish process-structure-property linkages for this system